Introduction

The SAP Extended Warehouse Management (EWM) module within the SAP ERP system is a comprehensive solution that enhances and extends warehouse management capabilities beyond those provided by traditional warehouse management (WM) modules. We focus on improving warehouse operations by providing advanced inventory management, order fulfilment and resource optimisation capabilities. This allows companies to increase the transparency, efficiency and accuracy of warehouse processes, enabling real-time tracking of stock movements, efficient picking strategies and optimised resource utilisation. EWM is designed to integrate seamlessly with other SAP modules to provide a complete solution for end-to-end supply chain management.

Process EWM module

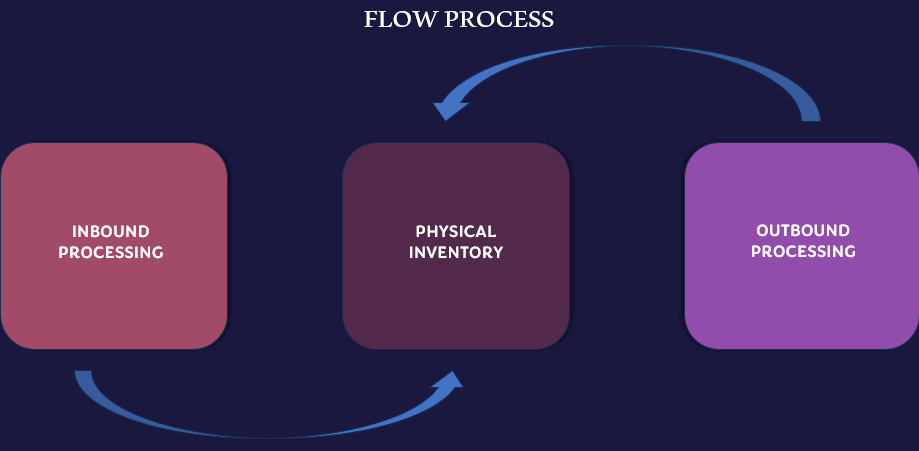

The processes of the SAP Extended Warehouse Management (EWM) module include three main concepts: Inbound Process, Outbound Process and Physical Inventory Process.

Together, these three processes form the core functionality of SAP EWM, ensuring efficient warehouse management, accurate inventory management and optimised supply chain operations.

Inbound Process

The Inbound Process in the SAP Extended Warehouse Management (EWM) module refers to all the activities involved in managing the flow of goods into the warehouse. This includes processing incoming shipments, unloading, performing quality checks and placing orders in designated storage locations. The main components of this process :

- Goods Receipt : the process begins at goods receipt, where the system registers the arrival of the product at the warehouse. This stage involves confirming receipt of items for incoming orders or deliveries.

- Handling and storage : Once goods have been received, products are often unloaded from incoming vehicles. The EWM system manages the unloading process and facilitates the placement of goods into pre-determined storage locations within the warehouse. The storage process may involve considerations such as determining the storage location based on warehouse layout, storage type and product characteristics.

- Quality control : EWM handles the quality control processes for incoming products. This involves checking that incoming goods comply with predetermined quality standards. Depending on the results of the inspection, goods may be accepted, rejected or flagged for further inspection.

- Decomposition : When products are received in consolidated shipments, the receiving process may include decomposition, which involves dividing larger shipments into individual items or smaller units for more efficient storage and handling.

- Handling units : EWM enables the management of handling units, which are containers or material

- Document management : The module allows you to manage associated documents such as shipping documents, packing lists and delivery notes linked to the import process. This documentation is important for maintaining accurate records and supporting traceability.

- Cross-docking : EWM supports cross-docking, a strategy in which incoming goods are immediately transferred from the receiving area to the shipping area without the need for storage. This strategy is used to speed up the fulfilment of customer orders.

The incoming process in EWM is tightly integrated with other SAP modules, such as Materials Management (MM) and Sales & Distribution (SD), ensuring a seamless and consistent flow of data throughout the enterprise resource planning process.

Subscribe to the Rapid Views Newsletter !

Stay up to date with our latest blog posts, upcoming webinars and news!

Outbound Process

The outbound process in the SAP Extended Warehouse Management (EWM) module refers to all the activities and procedures involved in managing the flow of goods out of the warehouse. It encompasses the processes of order fulfilment, item picking and packing, and the subsequent dispatch or delivery of products to customers. The key components of the outbound process in EWM are as follows :

- Outbound order processing : the process begins with the receipt of outbound orders from SAP Sales and Distribution (SD) or other relevant modules. Outbound orders can include sales orders, transfer orders or delivery orders.

- Order Confirmation : Once the outbound orders have been received, the EWM system confirms stock availability and confirms the order. This step involves checking the inventory to ensure that the requested items are in stock and can be allocated to the outbound order.

- Picking : The picking process involves selecting items from their storage locations according to the requirements of the outbound order. EWM supports various selection strategies, such as wave selection, cluster selection and zone selection, to optimise the selection process and increase efficiency.

- Packaging : After collection, items are packaged using appropriate packaging materials. EWM enables the management of packaging materials and supports packaging processes that may include the consolidation or separation of items according to specific business requirements.

- Handlers : EWM manages handlers during the shipping process, ensuring that items are correctly grouped and packed for shipment. Handling units can include pallets, cartons or other containers.

- Loading : Once items have been packed, the next step is the loading process. EWM helps to optimise loading by providing advice on loading sequences and ensuring that the right items are loaded onto the right transport vehicle.

- Shipping : The shipping process ends with the goods being transported to the designated location. EWM integrates with carriers and shipping services, creates shipping documents and labels, and tracks the status of shipments.

Physical Inventory Process

The Physical Inventory (PI) process in the SAP Extended Warehouse Management (EWM) module involves systematically counting and verifying the actual stock level in the warehouse and matching it with the inventory recorded in the system. This process is essential for maintaining accurate inventory records, identifying discrepancies and ensuring reliable supply chain operations. A key element of the inventory process in EWM is ‘count and control‘. During inventory management, warehouse staff physically count items in specific storage locations. The aim is to verify the accuracy of the inventory recorded in the system by comparing it with the quantity actually available.

Conclusion

In conclusion, the implementation of the Extended Warehouse Management module offers significant benefits to users by optimising and improving warehouse operations. As well as optimising day-to-day warehouse operations, it also contributes to the overall success of your business by increasing customer satisfaction, reducing costs and facilitating adaptability to changing business needs.